Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

The ABS series is a family of inks for printing on a wide variety of resins including polystyrene, ABS, and AS They are also ideal for vacuum forming with clear and sharp results. The inks may be used with or without diluents but only specified solvents may be used. They must never be mixed with other inks.

| Ink type | Air-drying inks consisting of acrylic resin, other special resins, and solvents, and specifically adjusted to prevent cracking when applied to plastics such as ABS. |

| Usage | Ideal for printing, coating, and spraying on polystyrene, ABS, and AS resins. |

| Finish | Gloss finish with good leveling. |

| Diluent | Standard solvent (T-472), slow-dry solvent (T-971) |

| Retarder | Use T-979 retarder in summer or hot temperature. |

| Wash-up | Use T-902 solvent for economical wash-up. |

| Coverage | Approximately 27m² per kilogram using a 250-mesh screen. |

| Drying time | Air-dries (20°C) in about 30 minutes or quicker by thermal curing. |

| Adhesion | Ideal for a wide variety of plastic products, polystyrene, ABS, AS, and other molded resins, and foamed polystyrene |

| Screen mesh | Use of nylon or Tetron screens of 200 or higher mesh numbers is recommended. |

| Notes | Cracks may occur when overprinting on injection-molded items. |

| Caution | ABS inks have low alcohol resistance. |

The STR series is a family of inks of high adhesion power and alcohol resistance for printing on polystyrene, and AS and ABS surfaces.

| Ink type | Air-drying inks consisting of acrylic resin, carefully formulated to prevent cracking in the plastic material. |

| Usage | Polystyrene, high-impact styrene, AS and ABS plates, molded items, and sheets in general. |

| Finish | Gloss finish of good leveling. |

| Coverage | Approximately 25m² per kilogram using a 250-mesh screen. |

| Drying time | Dries in about 30 minutes when allowed to stand at 20°C or more quickly by thermal curing (60°C x 10-15 minutes). For alcohol resistance and other tests, wait for at least 2 days after printing. |

| Adhesion | Adheres well to a wide variety of plastic products, polystyrene, high-impact styrene. AS, ABS, and other molded items. Also suitable for PVC acrylic, polycarbonate, and other plates. |

| Diluent | Standard solvent (T-475), slow-dry solvent (T-962), retarder (T-982). |

| Wash-up | T-15 |

| Notes | Cracks may occur when overlap printing on injection-molded items or near injection gates. |

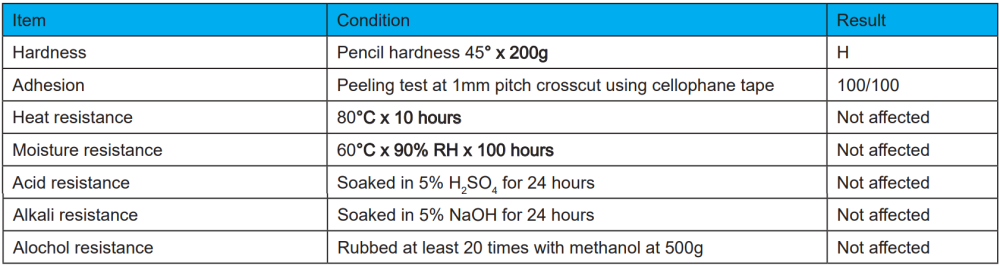

| Material | Styrene Plates |

| Thermal Curing | STR-120 and 710 measured after thermal curing |

| Air Drying | (60°C x 30 minutes) or 1 week of air-drying |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)