Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

The 2500 series is a family of inks for printing on acrylic resins, and features outstanding weather resistance and clarity for screen printing on nameplates and electrical signs. The inks in this series are air-drying inks of low odor. They are free of peeling. discoloration, fading, or cracking at the time of forming. Use of exclusive solvents is highly recommended as acrylic resins are affected relatively easily by solvents. Moreover, the inks in this series must never be mixed with other inks,

| Ink type | Air-drying ink of low odor level consisting of acrylic resin, other special resins, and high-quality coloring pigments of high weather resistance. |

| Usage | Ideal for printing on nameplates and electrical signs made of acrylic resin and other plates. |

| Finish | Semi-gloss (slightly varying with the color) finish with good leveling and smooth film of outstanding pattern reproduction. Outstanding transparency and coloring for electrical signs. |

| Coverage shading power | Outstanding covering power of black color for nameplates. |

| Clarity | Eight transparent colors are available. 110 (electrical sign white) emphasizing semitransparent white is also available for lining under electrical signs. |

| Weather resistance | This series of inks have excellent weather resistance when printed on the interior surface of acrylic signs. Weather resistance is reduced when printed on the exterior. Also, chalking may occur with high concentration colors. Sample before use |

| Secondary Processability | Outstanding secondary processability (heat resistance, etc.) after printing, especially for postprinting forming of electrical signs without cracking or discoloration |

| Adhesion | Outstanding adhesion especially to acrylic resin plates, plus weather resistance for use with electrical signs. |

| Drying time | Air-dries (20°C) in about 30 minutes (sets to touch). Curing for 5-10 minutes after printing at temperature 60-80°C will further increase adhesion, Troubles due to drying conditions and other factors may result when printing on molded signboards, especially when they are let to dry on racks in poorly ventilated and cold places. These problems can be prevented by the addition of quick-dry solvent and by thermal curing Acrylics resin plates should be stored carefully as they easily absorb moisture and cracks will result when printing on moist resins. |

| Viscosity adjustment | Ideal viscosity varies with the printing environment. Normally, an adequate working viscosity is obtained when T-2500 is added to the ink in proportion of 5-15 to 100 (ink). |

| Slow-dry solvent | Use T-2500S or T-980 for summer or precision printing. |

| Screen | Use of water-soluble cut film or photomechanical process in combination with Tetron or nylon screens of 200-300 mesh is recommended |

| Wash-up | Use T-15 for economical wash-up. |

| Notes | The inks in this series must never be mixed with other inks. Use of exclusive solvents is highly recommended as ordinary solvents will affect drying time and cause crazing and other problems in the material and the printed film. |

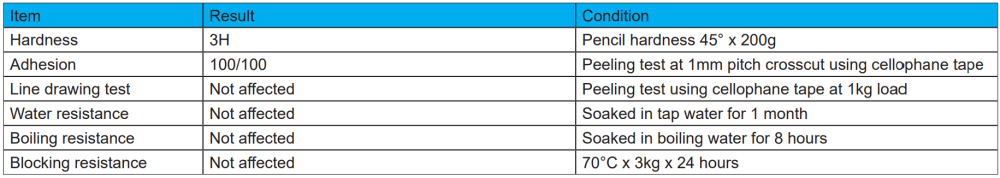

| Material | Acrylic plate (extruded) |

| Drying | 1 week at room temperature (20°C) |

The CAV MEIBAN series is a family of semi-gloss inks for printing on acrylic, polycarbonate, and PVC nameplates with outstanding leveling and printability. The CAV MEIBAN series includes standard colors, while the CAV Transparent series includes transparent or metallic colors. All standard colors are set to the concentrated pigmentation type.

| Ink type | Evaporation-dry, one-pack type. |

| Usage | For printing on acrylic, polycarbonate, and PVC sheets to produce nameplates. |

| Finish | Semi-gloss finish of outstanding leveling. |

| Coverage | Approximately 25m² per kilogram using Tetron 250-mesh screens. |

| Drying time | Dries naturally (20°C) in 30 minutes or in only 10 minutes by thermal curing (60°C). |

| Adhesion | Good adhesion to acrylic, polycarbonate, PVC, and ABS plates, sheets, and molded items. Overcoatability is also excellent. |

| Diluent | Standard solvent (T-945), slow-dry (T-947), retarder (T-980). |

| Wash-up | T-15 |

| Notes | Viscosity tends to increase 4 hours after adding gold metallic powder. Printing must begin within this time frame. Transparent colors are available separately in the CAV Transparent series. Use CAV Transparent inks when metallic colors of good leveling and stability are required. |

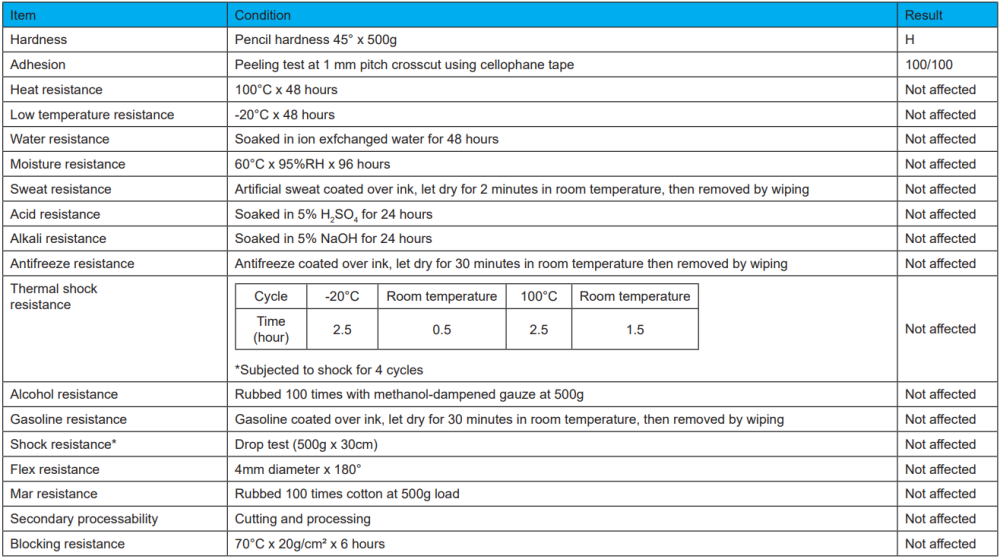

| Material | Polycarbonate resin plates (0.5mm thick) and acrylic plates (extruded). Items marked with *only apply to polycarbonate resin plates. |

| Ink | CAV MEIBAN-710, 120, and 510 |

| Drying | 60°C x 15 minutes, left to sit for 3 days before testing. |

The TSN Series is a family of PVC-free inks. It forms a soft film after printing, and possesses great heat resistance, suitable for heat-forming

| Ink type | 1-part evaporating type acrylic ink. |

| Usage | Suitable for heat formed products, PC, PMMA, PVC films and plates |

| Finish | Semi-gloss finish |

| Coverage | Approximately 27m² per kilogram using a 250-mesh screen |

| Drying time | Air-dry: 20°C for 60 minutes |

| Thermal Curing | 60°C for 40 minutes, or 80°C for 10 minutes |

| Diluent | Standard Solvent: T-945 Slow-drying Solvent: T-954 Retarder: T-980 |

| Wash-up | Use T-31 for economical wash-up |

| Other | Cracking might occur based on variance in substrates. Please use compatible solvents. Based on variance in printing condition, over-drying may lead to negative conditions such as mesh-clotting. Please use TSN Slow Dry ink. |

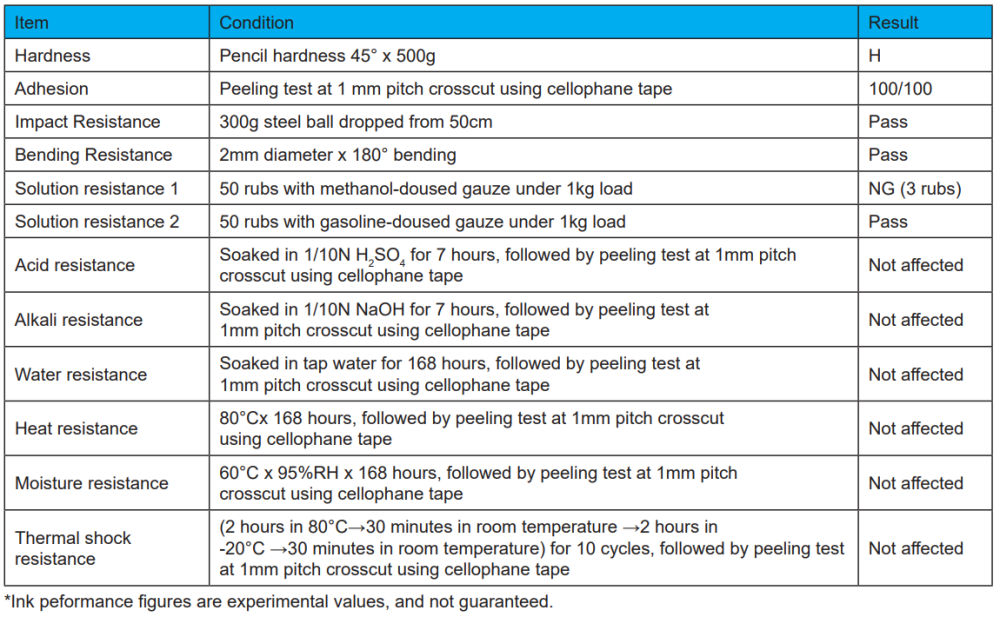

| Material | Polycarbonate plate |

| Ink | TSN120, 710 |

| Curing | 30 minutes in 60°C, followed by 1 day in room temperature. |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)