Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

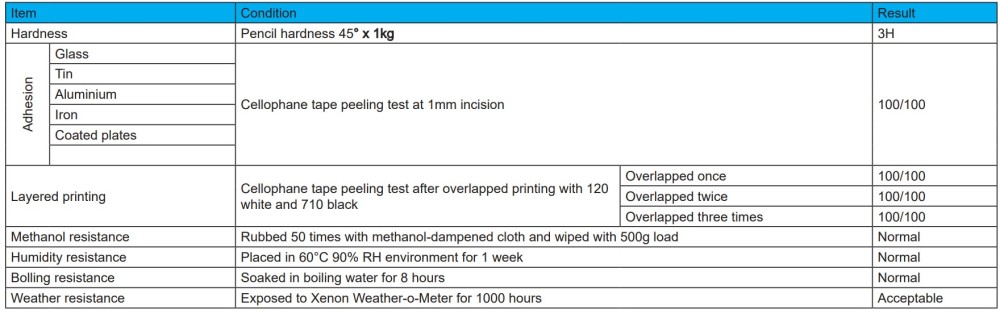

The HGI RX002 series is a family of acrylic urethane based inks designed for thermal curing. They feature outstanding adhesion to glass, metals and coated metals, and are highly resistant to weathering and moisture.

| Ink type | One-pack thermal curing ink blended with acrylic urethane. |

| Usage | Applicable to glass, aluminium, iron and coated metal. |

| Features | • Gloss finish with excellent levelness. • Requires thermal curing at high temperatures. • One-pack ink with high printability. • Highly suitable for outdoor use, designed for outdoor glass surfaces. • Improved resistance to moisture and boiling water compared to existing products for glass. |

| Diluent | Standard solvent T-965 |

| Wash-up | T-31 |

| Screen | 200-300 mesh/inch polyester or nylon screens |

| Drying Time | 30 minutes at 150°C |

| Notes | • HGI RX002 series inks may exhibit inferior performance due to moisture in air. • Store in dark and cool spaces with minimum exposure to air. • Multi-layered printing may result in poor adhesion. When performing such operations, please allow previous layers to set to touch dry (at a lower temperature, 10 minutes at 100°C recommended) and hard-dry only after all layers are applied. • Viscosity of the ink may vary based on colour. Please adjust with diluent accordingly. |

| Ink | HGI RX002 HGI RX002 120 White, 710 Black |

| Material | Glass, aluminium, iron, coated metal |

| Screen | Polyester 250-mesh screen |

| Squeezee | Medium-hard |

| Printing method | Hand printing |

| Dilution | T-965 20% |

| Drying | 30 minutes at 150°C |

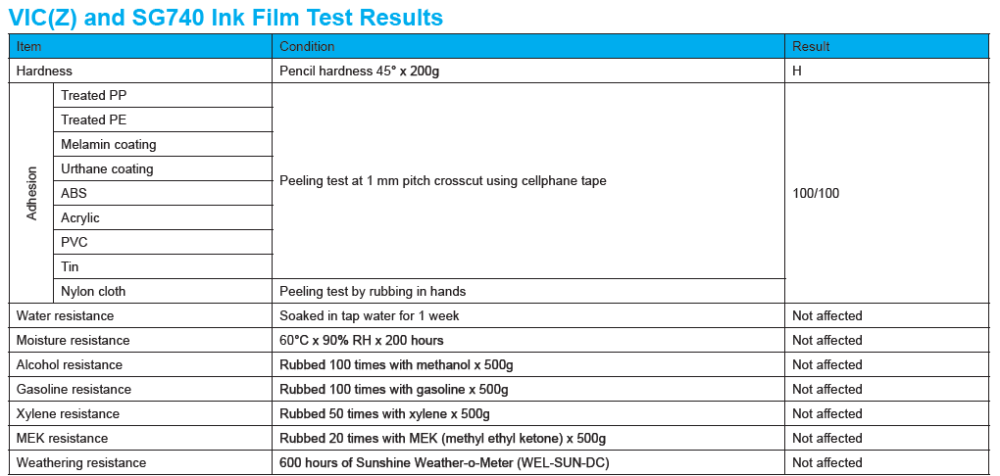

The SG740 series is a family of two-part reaction inks that dry more quickly than other two-part reaction inks for higher work efficiency. Their outstanding adhesion power and superb moisture and solvent resistance make them ideal for printing over treated POM (polyacetal), treated PE, treated PP, ABS, acrylic, PVC and other materials. SG740 is a sister series to the VIC series.

| Ink type | Quick-drying, two-part reaction ink using an isocyanate hardener. |

| Usage | Outstanding adhesion power makes them ideal for printing over treated PP and PE, treated POM (polyacetal) coats (especially urethane coats), ABS acrylic, PVC, nylon cloth, and other materials. |

| Finish | Generally semi-gloss finish and outstanding resistance with solvents although the quality varies with the color. |

| Drying time | Natural or thermal curing. Sets to touch in 40 minutes at room temperature (25°C), hard dry in 1 week at room temperature or 30 minutes by thermal curing (80°C) + 2 days air drying. Heat treatment at 120°C for 20 minutes is recommended for best results on metals. |

| Mixing ratios | Add hardener (transparent) to the main agent (colored) at the ratio of 1:10, and agitate them well before use. Use within the pot life of 6-8 hours after which the mixture will turn to gel or lose its designed physical properties. |

| Diluent | Use the following three types of solvents (10-15% weight) to adjust viscosity: standard solvent (T-926), slow-dry solvent (T-927), retarder (T-980). |

| Wash-up | Use T-15 for economical washing of the plate and other tools. |

| Performance | Performance is identical to that of the VIC series. |

| Caution | • The hardener for the SG740 series is extremely sensitive to moisture and should be used as soon as it is unpacked. Foaming and blisters may result under some printing conditions. Add CARE 20 or CARE 50 (1-2%) to the ink to prevent foaming or blisters. • The printed film is somewhat thinner compared to that of the VIC series. • Use of gold metallic powder is not recommended as it will cause a chemical reaction leading to gelation. There is no problem with silver metallic powders. |

| Material | Treated PP |

| Ink | VIC-120, 710, SG740-120, 710 |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)