Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

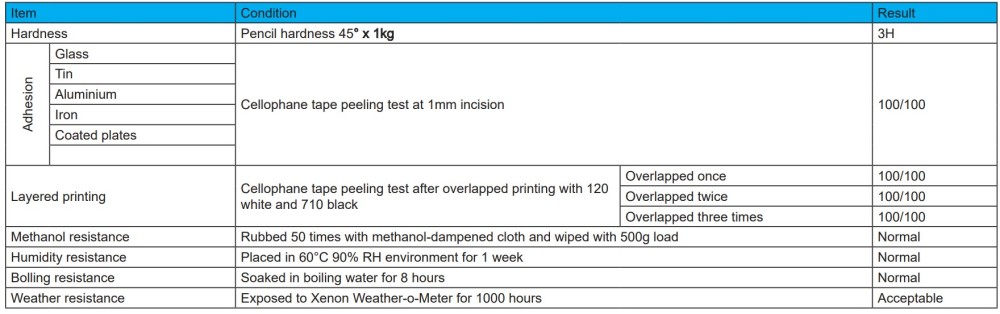

The HGI RX002 series is a family of acrylic urethane based inks designed for thermal curing. They feature outstanding adhesion to glass, metals and coated metals, and are highly resistant to weathering and moisture.

| Ink type | One-pack thermal curing ink blended with acrylic urethane. |

| Usage | Applicable to glass, aluminium, iron and coated metal. |

| Features | • Gloss finish with excellent levelness. • Requires thermal curing at high temperatures. • One-pack ink with high printability. • Highly suitable for outdoor use, designed for outdoor glass surfaces. • Improved resistance to moisture and boiling water compared to existing products for glass. |

| Diluent | Standard solvent T-965 |

| Wash-up | T-31 |

| Screen | 200-300 mesh/inch polyester or nylon screens |

| Drying Time | 30 minutes at 150°C |

| Notes | • HGI RX002 series inks may exhibit inferior performance due to moisture in air. • Store in dark and cool spaces with minimum exposure to air. • Multi-layered printing may result in poor adhesion. When performing such operations, please allow previous layers to set to touch dry (at a lower temperature, 10 minutes at 100°C recommended) and hard-dry only after all layers are applied. • Viscosity of the ink may vary based on colour. Please adjust with diluent accordingly. |

| Ink | HGI RX002 HGI RX002 120 White, 710 Black |

| Material | Glass, aluminium, iron, coated metal |

| Screen | Polyester 250-mesh screen |

| Squeezee | Medium-hard |

| Printing method | Hand printing |

| Dilution | T-965 20% |

| Drying | 30 minutes at 150°C |

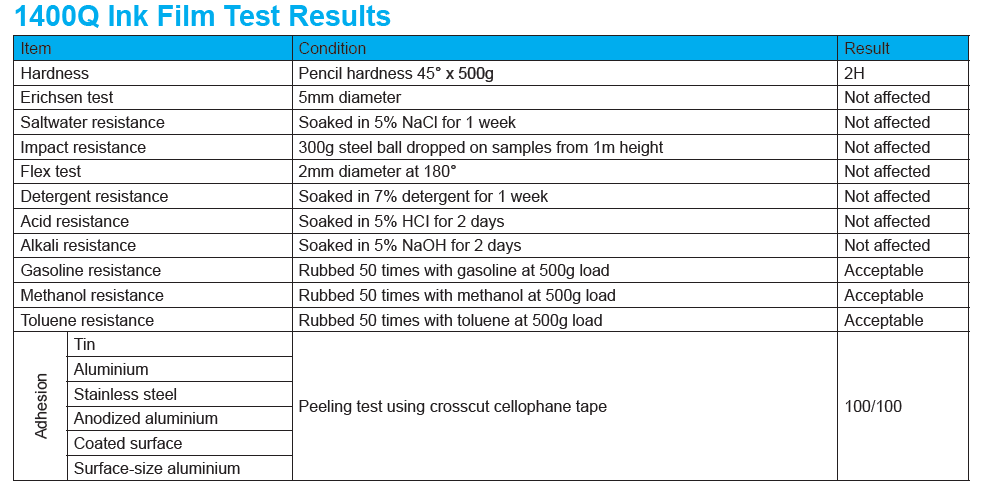

The 1400Q series is a family of one-pack, curing-type polyester and melamine inks of good leveling for screen printing on metals (aluminium, anodized aluminium, tin, stainless steel) and metallic coats where resistance against solvents and alcohol is required. They feature particularly good flexibility for printing on material subjected to stamping, bending, embossing, and other mechanical processes.

| Ink type | One-pack thermosetting inks in which polyester and melamine resins are blended. This type of ink normally requires curing at high temperature but the inks in the 1400N series contain a catalyst so that they may be cured at a relatively lower temperature. They feature outstanding flexibility (resistance to stamping, bending, embossing) and recoatability (overprinting may begin after 30 minutes of curing at 150°C). |

| Usage | Aluminium, surface-size aluminium, anodized aluminium, tin, stainless steel, and their coats. |

| Finish | Gloss finish with good levelling. |

| Drying time | Heating is required. Standard drying time is 30 minutes at 150°C. |

| Diluent | Standard solvent T-980 or T-990 |

| Adhesion | Strong adhesion to metals and metallic coats. For glass printing, add 2-3% of Care 73 to improve the adhesion and water resistance. |

| Wash-up | T-31 |

| Ink | 1400Q-120(white) |

| Drying | 150’C x 30 minutes |

| Material | Aluminium plate |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)