Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

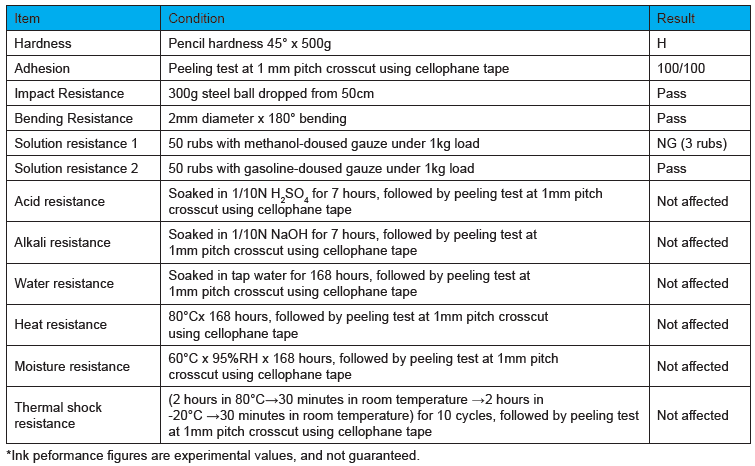

PID series is two part reaction ink developed for insert/in-mold forming on Polycarbonate, PET, etc. The ink can produces good adhesion, flexibility and heat resistance applicable for making a key pad film of mobile phone parts, home appliances, etc

| Drying | 80°C x 30min is recommended |

| Screen mesh | Tetron or Nylon 250~350 are recommended |

| Wash-up | T-905 or T-31 |

| Mixing ratio | PID hardener: by weight Ink: PID Hardener = 100 : 20 *Pot life is about 6~8 hours after mixing with hardener |

| Solvent | T-926 (standard solvent) |

| Usage | Mainly Polycarbonate and PET for insert/in-mold forming, Good adhesion, flexibility and heat resistance suitable for forming process |

| Ink type | Two part reaction polyester ink (available for air-drying) |

| Material | Polycarbonate plate |

| Ink | PID120, 710 |

| Curing | 30 minutes in 60°C, followed by 1 day in room temperature. |

PCI RX01series is two part reaction ink developed for insert forming on Polycarbonate.The ink can produces good adhesion, flexibility and heat resistance suitable for forming process.

| Ink type | Two part reaction polyester ink |

| Usage | Mainly Polycarbonate for insert forming Good adhesion, flexibility and heat resistance suitable for forming process |

| Solvent | T-900 (standard solvent) T-910 (slow drying solvent) |

| Mixing ratio | PCI RX01 ink : SI-hardener = 100 : 5 |

| Wash-up | T-31, T-40 |

| Screen mesh | Tetron or Nylon 200~300 are recommended |

| Drying time | 80°C x 30min is recommended |

| Others | VF-hardener should be used as soon as possible as after mixing with PCI RX01 ink since it very sensitive to moisture. |

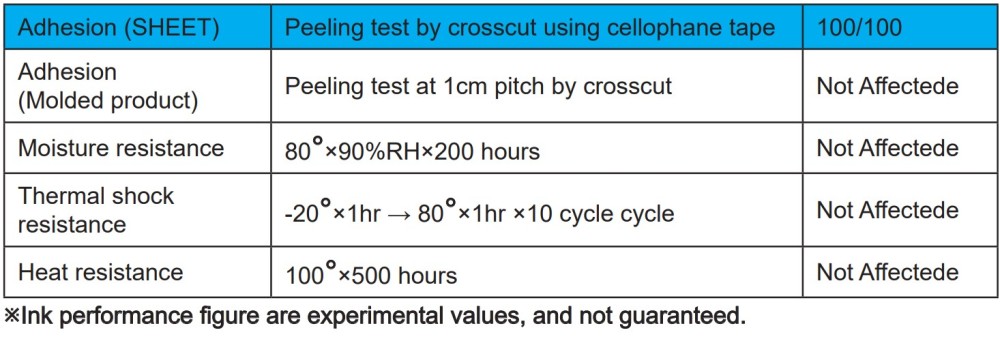

HF PCL Series is single pack reaction ink developed for insert forming on Polycarbonate. The ink can produced good adhesion, flixibility and heat resistance suitable for forming process

| Ink type | Single pack polyester ink |

| Usage | PMMA, PC, ABS, etc Pattern A 1st layer HF PCL 710 black : T922 = 100 : 20 (60° x 10-30min) 2nd layer HF PCL 125 Pure White : Y3411 = 100 : 20 (60° x 10-30min) 3rd layer HF PCL 800 Medium Clear : Y3411 = 100 : 20 (60° x 3min) Pattern B 1st layer HF PCL 710 black : T922 = 100 : 20 (60° x 10-30min) 2nd layer HF PCL 710 black : Y3411 = 100 : 20 (60° x 30min) |

| Solvent | T-922 (standard solvent) |

| Wash-up | T-31 or T-40 |

| Screen mesh | Tetron or Nylon 200~300 are recommended |

| Drying | 80°C x 30min is recommended |

| Material | Polycarbonate plate |

| Ink | HF PCL 120, 710 |

| Curing | 30 minutes in 60°C, followed by 1 day in room temperature. |

The VIC series is a family of two-part reaction urethane inks that dry more quickly than other two-part reaction inks. They feature outstanding adhesion, good moisture and solvent resistance, and may be printed over treated PP and PE as well as coated surface. ABS, acrylic, PVC, and other materials.

| Ink type | Quick-drying, two-part reaction inks using an isocyanate hardener. |

| Usage | Treated PP and PE coats (especially urethane coats), ABS, acrylic, PVC, nylon cloths, etc. |

| Finish | Generally semi-gloss finish plus solvent-resistant film, although the quality varies slightly with the color. |

| Drying time | Air or thermal curing. Sets to touch in 30 minutes at room temperature (25°C); 5 minutes by thermal curing at 60°C. Hard dry in 1 week at room temperature; 20 minutes by thermal curing at 80°C + 2 days air drying. |

| Mixing ratios | Add hardener (transparent) to the main agent (colored) at the ratio of 1:10, and agitate them well before use. Use within the pot life of 6-8 hours, after which the mixture will turn to gel or lose its designed physical properties. Pot life may vary based on environmental sectors. |

| Diluent | Use the following types of solvents (10-15% weight) to adjust viscosity: standard solvent (T-926), slow-dry solvent (T-927), retarder (T-980). |

| Wash-up | Use T-15 for economical wash-up. |

| Notes | VIC series hardeners are very sensitive to humidity, so VIC inks should be used as soon as possible after opening. After the addition of gold metallic powder, a reaction will occur that causes the ink to gel rapidly.The inks should not be used in cases of such reaction. |

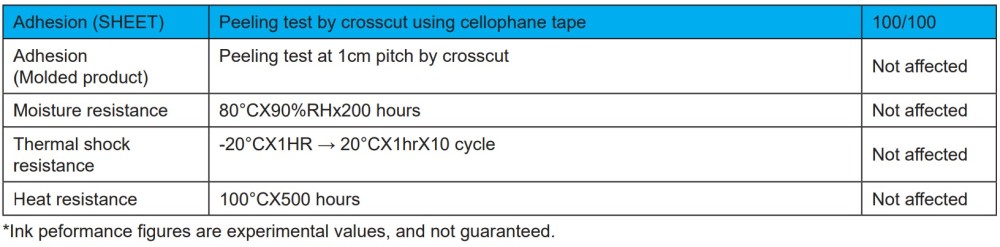

HF SKY-series is a family of two-part reaction inks that is compatable with IMD/IML Application.

| Type | Two part thermal curing ink. |

| Usage | PMMA PC ABS etc. |

| Feature | Gloss finish |

| Diluent | Standard T-980 |

| Mixing ratios | HF SKY 120 White a hardner : A Hardener = 100 : 3 HF SKY 710 : A HARDENER = 100 : 3-10 *if high stretchability is required, less ratio of hardener is better. If there is no requirement of stretchability, high ratio of hardener is better. |

| Washing solvent | T-15 |

| Drying time | 80° x 5min (Temporary drying) 80° x 1-2hours (Final drying after print binder) Example of drying for each layer 1st HF SKY 710 (80° x 5min) 2nd HF SKY 710 (80° x 5min) 3rd HF SKY 710 (80° x 5min) 4th HF SKY 710 (80° x 5min) 5th JT50 Binder (80° x 2hours) Longer drying time give higher heat and wash out resistance |

| Material | Polycarbonate plate |

| Ink | HF SKY 120, 710 |

| Curing | 30 minutes in 60°C, followed by 1 day in room temperature. |

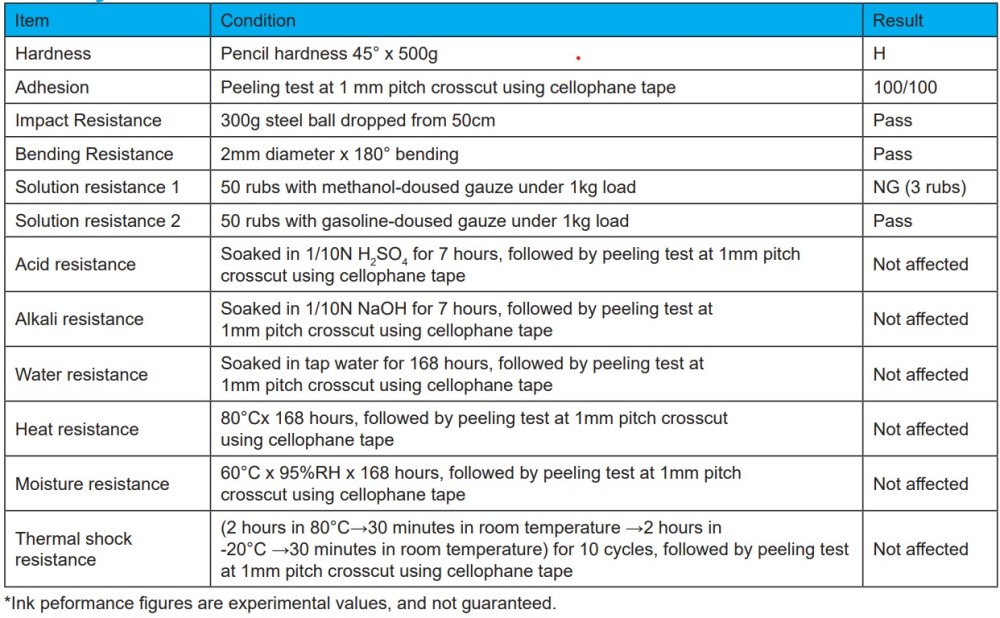

The HF HSD series is a family of two-part reaction type inks. They can be widely applied to various materials, and offer excellent printability. Having a flexible ink layer, they can also be applied in in-mold decoration. This series of inks is halogen-free and environment-friendly.

| Ink type | Polyacrylate-based two-part isocyanate hardener-type. |

| Usage | Excellent adhesion on various materials, suitable for materials such as processed PP, coated surfaces, ABS, PMMA, hard-coated PMMA, PC, processed PET, and aluminium. |

| Features | • Gloss Finish • Widely applicable, demonstrates excellent adhesion to most substrates. • Excellent moisture and solvent resistance. • Halogen-free |

| Diluent | • Standard solvent: T-926 • Slow-dry solvent: T-927 • Retarder: T-980 |

| Mixing ratio | • Ink: D-Hardener = 100:10) • Gel phenomena may occur after 6-8 hours of usage at room temperature after mixing, leading to reduced physical performance. |

| Washup | T-15/T-31 |

| Screen | 200-300 mesh/inch polyester or nylon screens recommended. |

| Drying time | • Sets to touch-dry in 40 minutes at 25°C. • Hard-dries in 1 week (air-drying) or 30 minutes at 80°C+2 days air-drying. • When applied to metal substrates, thermal curing for 20 minutes at 120-150°C is required for optimal results. |

| Notes | • When used on electroplated film, dilute with solutions T-900 or T-910 to prevent solvent attacks to the substrate. (Verification is advised based on substrate differences) • D-Hardener is extremely sensitive to moisture. Use as soon as possible after opening. • Bubbles and/ or pin-holes may form based on printing conditions. Add 1-2% (by weight) of CARE 13 as needed. • Add 3-5% of CARE 73 to enhance adhesion to glass and resistance to boiling and alcohol. |

| Material | Polycarbonate plate |

| Ink | HF HSD 120, 710 |

| Curing | 30 minutes in 60°C, followed by 1 day in room temperature. |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)