Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

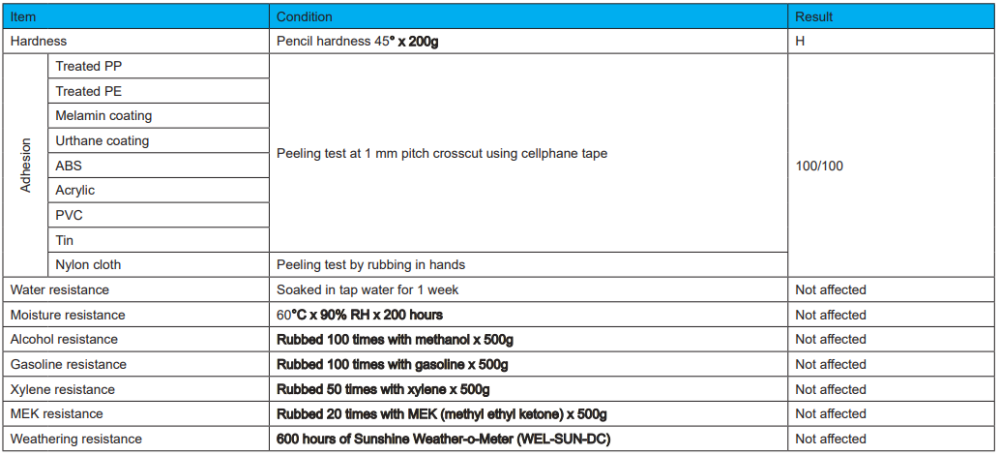

The VIC series is a family of two-part reaction urethane inks that dry more quickly than other two-part reaction inks. They feature outstanding adhesion, good moisture and solvent resistance, and may be printed over treated PP and PE as well as coated surface. ABS, acrylic, PVC, and other materials.

| Ink type | Quick-drying, two-part reaction inks using an isocyanate hardener |

| Usage | Treated PP and PE coats (especially urethane coats), ABS, acrylic, PVC, nylon cloths, etc |

| Finish | Generally semi-gloss finish plus solvent-resistant film, although the quality varies slightly with the color |

| Drying time | Air or thermal curing. Sets to touch in 30 minutes at room temperature (25°C); 5 minutes by thermal curing at 60°C. Hard dry in 1 week at room temperature; 20 minutes by thermal curing at 80°C + 2 days air drying. |

| Mixing ratios | Add hardener (transparent) to the main agent (colored) at the ratio of 1:10, and agitate them well before use. Use within the pot life of 6-8 hours, after which the mixture will turn to gel or lose its designed physical properties. Pot life may vary based on environmental sectors. |

| Diluent | Use the following types of solvents (10-15% weight) to adjust viscosity: standard solvent (T-926), slow-dry solvent (T-927), retarder (T-980). |

| Wash-up | Use T-15 for economical wash-up |

| Notes | VIC series hardeners are very sensitive to humidity, so VIC inks should be used as soon as possible after opening. After the addition of gold metallic powder, a reaction will occur that causes the ink to gel rapidly.The inks should not be used in cases of such reaction. |

| Material | Treated PP |

| Ink | VIC-120, 710, SG740-120, 710 |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)