Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

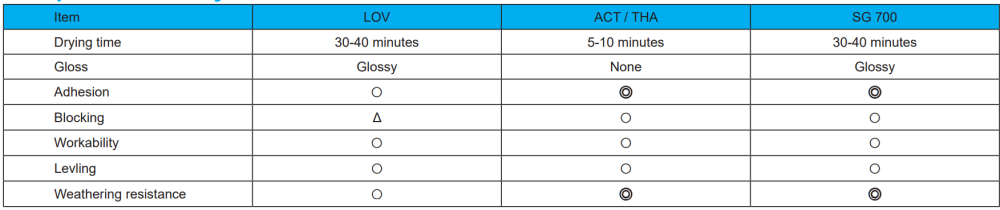

The LOV series consists of vinyl-based inks of high-gloss finish and resistance against weathering, designed for high-quality printing on vinyl products, vinyl-coated paper, and the like. The printed film is very rugged to withstand outdoor weathering while maintaining adequate softness. Weathering resistance is assured for all colors without bleeding. Inks in this series are ideal for screen printing requiring a sharp finish.

| Ink type | Pigments and resins are blended in with low-odor, air-drying inks to produce excellent luster and durability. Solvents and drying retarders may be added as needed. |

| Usage | Ideal for all vinyl products including vinyl-coated paper, stickers, cloths, molded products, toys, and shower curtains. |

| Finish | Soft luster with good leveling. |

| Coverage | Approximately 30m2 per kilogram on a 250-mesh tetron screen. |

| Drying time | Air-dries(20°C) in approximately 30 minutes, or quicker with thermal curing. |

| Screen | Use of water-soluble cut film or photomechanical process is recommended. |

| Mesh | Tetron or nylon screens having a mesh number of 200 or larger for finer finish. |

| Diluent | Standard solvent (T-912) or slow-dry solvent (T-920). |

| Retarder | Use of T-980 gives an ideal fluidity. |

| Wash-up | Use T-911 or T-15 for economical wash-up. |

| Weathering | Inks in this series are highly resistant against weathering although it varies with the color. |

| Resistance | Extra resistance against weathering is available upon request. |

| Clarity | Nontransparency varies with the color. Transparent color inks (eight colors) are available. Please refer to the gloss color cards for color tones. |

| Notes | These inks adhere very well to almost all vinyl surfaces but performance may be affected by wax or other undesired substances that may adhere to PVC leather, vinyl plastic coating, cast items, or dyes. Testing is recommended. |

Ease of use was emphasized in developing the vinyl-based inks in the ACT series. Outstanding compatibility for printing and workability differentiate them from other PVC inks. They are also economical, quick drying screen printing inks of good adhesion and low odor levels applicable for a wide variety of vinyl products.

| Ink type | Air-drying inks of low odor consisting of vinyl resins, and high-quality pigments. |

| Usage | Ideal for all vinyl products including toys, artificial leathers, and other soft vinyl, hard vinyl, PVC and stickers. Often used for marathon printing. Matte finish with good leveling of smooth screen printing |

| Finish | Matte finish with good leveling of smooth screen printing film. |

| Drying time | Air-dries (20°C) in approximately 5-10 minutes, or quicker with thermal curing, depending on the material and work environment. Overcoating can take place within 1-2 minutes, making the inks ideal for marathon printing. |

| Machine type | Ideal for marathon printing and high-speed cylinder press printing. |

| Adhesion | Inks adhere well to nearly all vinyl products. Presence of mold lubricant and plasticizer may affect adhesion. Testing is recommended. |

| Mesh | Tetron or nylon screens with a mesh number of 200 or higher. |

| Coverage | The printing area is about 25m² per kilogram at 250 mesh. |

| Secondary | The printed material may be fabricated safely without causing ink cracks or problems due to tackiness. |

| Processability | The printed film is flexible without peeling due to deflection. Blocking resistance is also good. |

| Diluent | Use standard solvent (T-912) for adjusting viscosity. Use slow-dry solvent (T-920) or retarder (T-980) when the drying time needs to be extended due to work environment, or for precision printing. |

| Retarder | Use of T-980 assures ideal fluidity. |

| Wash-up | Use T-911 or T-15 for economical wash-up. |

| Weathering Resistance | Extra resistance against weathering is available upon request. |

| Material | PVC sticker, soft vinyl film |

| Drying | 24 Hours at Normal Temperature (20°C) |

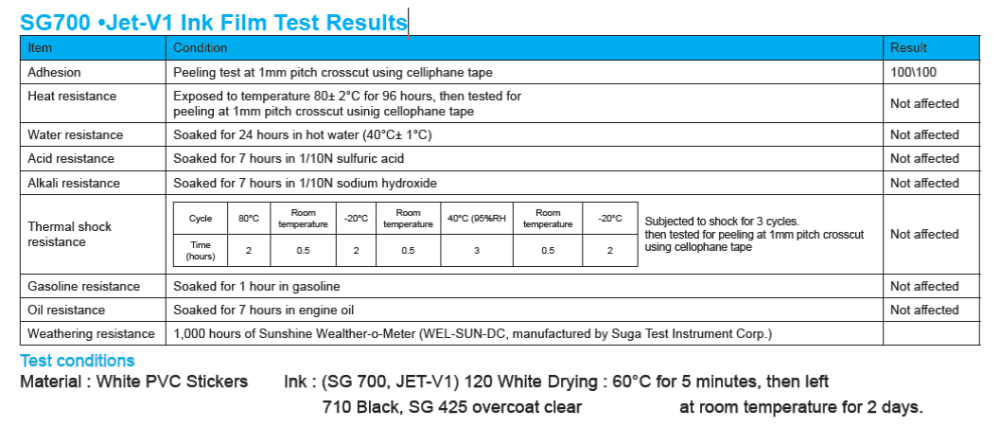

The inks in the SG700 series feature outstanding weathering resistance, flexibility, and clear overcoatability for printing on weathering-resistant marking film for outdoor signs, vehicles, etc. They produce sharp colors, are easy to mix for color matching. are ideal for printing (especially machine printing), and produce extremely stretchable ink films (80-130%). They are ideal for all vinyl products.

| Ink type | The inks in the SG700 series are air-drying inks blended with vinyl resins, other special resins, and highquality pigments that are highly resistant to weathering. |

| Finish | Printability is excellent, and the inks produce an ink film with a highly glossy finish and good leveling. |

| Drying time | Dries naturally (20’C) in approximately 30 minutes or quicker (about 5 minutes at 60°C) with thermal curing depending on the material and work environment. |

| Diluent | Standard solvent (T-912), slow-dry solvent (T-920), and retarder(T-980). |

| Retarder | Use of T-980 gives an ideal fluidity. |

| Wash-up | T-911 or T-15 |

| Weathering resistance | High resistance to weathering is an important feature of inks in this series, with the exception of 400 Ultra Blue and 208 Process Yellow. |

The JET series is solvent based ink which is developed for high speed screen printing. The ink is mostly effective using by the Jet Instant drying system combining a UV conveyer and an automatic cylinder press. Seiko Advance is devoted to develop the system which can show the full ability of automatic screen printing machines for the realization of a better working environment, through automation, saving labour and space. As a result, the Jet instant drying system combining an UV conveyer with solvent based inks was developed. The JET series is solvent based ink which is developed for high speed screen printing. The ink is mostly effective using by the Jet Instant drying system combining a UV conveyer and an automatic cylinder press. Seiko Advance is devoted to develop the system which can show the full ability of automatic screen printing machines for the realization of a better working environment, through automation, saving labour and space. As a result, the Jet instant drying system combining an UV conveyer with solvent based inks was developed.

| Usage | PVC materials, such as PVC sticker, marking film. Polycarbonate sheet. Paper, Vinyl coated paper and treated PP film. |

| Drying time | Printing as fast as 2500-3000 impression per hour with JET-ink by automatic cylinder press is possible and drying is easily synchronized by UV conveyer. |

| Feature/Finish | JET-V1 produce matte finishes with good levelling. |

| Diluent | T-920 (JET ink is formulated with suitable viscosity for printing straight from the container. However, the ink tends to become hard as its characteristic. Agitate well before use.) |

| Wash-up | T-911, T-15 |

| Material | White PVC Stickers |

| Ink | (SG 700, JET-V1) 120 White, 710 Black, SG 425 overcoat clear |

| Drying | 60°C for 5 minutes, then left 60°C for 5 minutes, then left |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)