Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

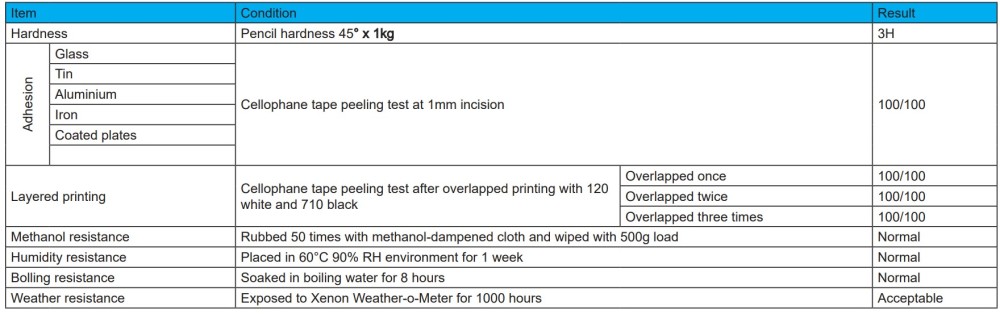

The HGI RX002 series is a family of acrylic urethane based inks designed for thermal curing. They feature outstanding adhesion to glass, metals and coated metals, and are highly resistant to weathering and moisture.

| Ink type | One-pack thermal curing ink blended with acrylic urethane. |

| Usage | Applicable to glass, aluminium, iron and coated metal. |

| Features | • Gloss finish with excellent levelness. • Requires thermal curing at high temperatures. • One-pack ink with high printability. • Highly suitable for outdoor use, designed for outdoor glass surfaces. • Improved resistance to moisture and boiling water compared to existing products for glass. |

| Diluent | Standard solvent T-965 |

| Wash-up | T-31 |

| Screen | 200-300 mesh/inch polyester or nylon screens |

| Drying Time | 30 minutes at 150°C |

| Notes | • HGI RX002 series inks may exhibit inferior performance due to moisture in air. • Store in dark and cool spaces with minimum exposure to air. • Multi-layered printing may result in poor adhesion. When performing such operations, please allow previous layers to set to touch dry (at a lower temperature, 10 minutes at 100°C recommended) and hard-dry only after all layers are applied. • Viscosity of the ink may vary based on colour. Please adjust with diluent accordingly. |

| Ink | HGI RX002 HGI RX002 120 White, 710 Black |

| Material | Glass, aluminium, iron, coated metal |

| Screen | Polyester 250-mesh screen |

| Squeezee | Medium-hard |

| Printing method | Hand printing |

| Dilution | T-965 20% |

| Drying | 30 minutes at 150°C |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)