Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

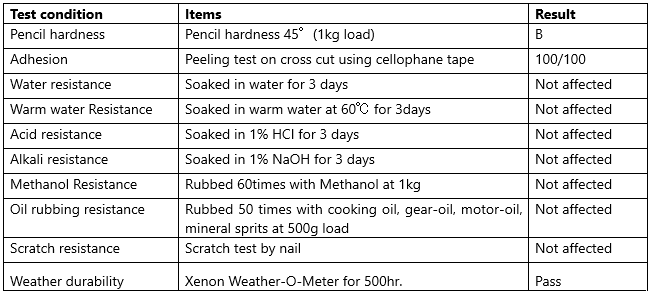

PPT series is developed for both treated and untreated polypropylene materials with good oil resistance and alcohol resistance.

| Ink type | One part air drying polyolefin ink |

| Usage | Untreated and treated polypropylene. |

| Feature | Semi-gloss finish, excellent oil, alcohol resistance and good printability. |

| Diluent | Standard solvent: T-900 Slow dry solvent: T-910 Super-slow dry solvent: T-950 |

| Washup | T-907 |

| Printing | Tetoron or nylon screens of 200~300/inch fabric mesh is recommended. Coverage : Approximately 20m2 /kg with 250/inch fabric mesh |

| Drying time | : Drying by set to touch *Air-drying at room temperature = 20℃ x 10~15min. : Hard drying Forced drying = 60℃ x 30~40min. |

| Others | * PPT inks may gel in cold weather but their original properties are not lost. Heat it in a water bath or stir it well before use. |

| Ink | PPT-120 White |

| Material | Untreated Polypropylene |

| Drying | 60℃ x 30min. + room temperature x 24hr. |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)