Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

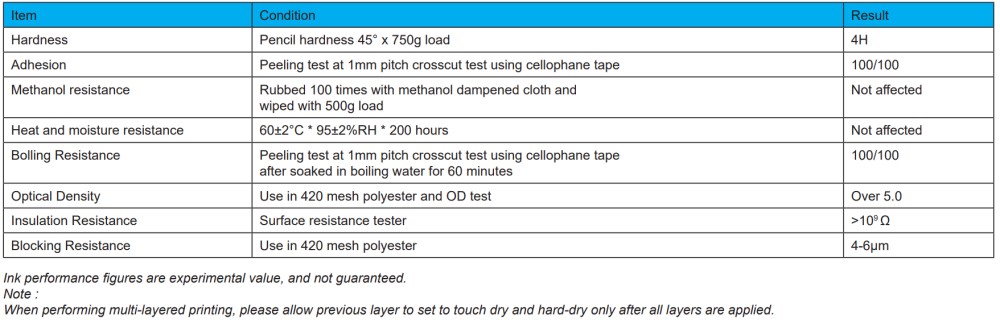

The HF GLV series is a ink developed for tempered glass, glass and metal-coated plates. This is an environmentally friendly product, the percentage of Chlorine and Bromine is 900ppm and total Halogen is below 1,500 ppm.

| Ink type | One pack thermal curing ink, hardener contained in inks requires thermal curing at high temperature. |

| Usage | Applicable for printing on tempered glass, stainless steel, aluminum, metal-coated plates |

| Features | Gloss finish with excellent levelness |

| Diluent | Standard solvent T-980 or T-965 |

| Mixing Ration | HF GLV ink (100): CARE 73 (3-5) |

| Wash-up | T-31 |

| Drying | 40 minutes at 150°C |

| Ink | HF GLV-710 black |

| Material | Tempered glass |

| Screen | polyester 420 mesh |

| Squeezee | 80 |

| Mixing Ratio | HF GLV-710: CARE 73 = 100:3 |

| Dilution | T-965 15-20% |

| Drying | 40 minutes at 150°C |

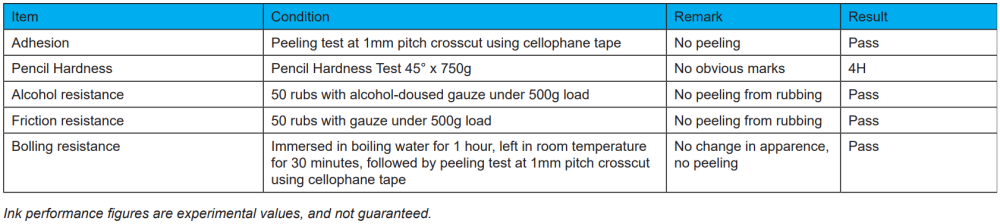

The HF SG460SSD NS series is a family of screen inks for use on reinforced glass, designed to not be affected by UV adhesives. It possesses better chemical and moisture resistance than common glass-targeted inks. With a Chlorine content of under 700ppm, a Bromine content of under 700ppm, and a total Halogen content under 1100ppm, this ink is designed with environmental concerns in mind.

| Ink type | 3-part urethane baking type |

| Usage | Various reinforced glass |

| Features | Strong adhesion and resistance to boiling and alcohol on reinforced glass |

| Diluent | Standard Solvent T-482 |

| Hardener | FA Hardener |

| Additive | Standard Coupling agent: CARE99 |

| Mixing Ration | Ink: Hardener: Coupling agent=70:30:3~5 Mixed inks may gel and lose physical properties if left in room temperature for 2-3 hours. Adhesion may vary based on glass textures. Try CARE 83 or CARE 183 in such conditions. |

| Curing | 150°C for 30 minutes |

| Screen Mesh | Tetron/ Nylon 200-420 screen mesh recommended |

| Other | CARE99 is sensitive to moisture. Please use as soon as possible after opening. |

| Ink | HF SG460SSD NS 710 Black |

| Hardener | FA Hardener |

| Additive | CARE99 |

| Mixing Ratio | 70:30:5 |

| Solvent | T-482 |

| Material | Reinforced Glass |

| Screen Mesh | Tetron 420 Mesh |

| Curing | 150°C for 30 mintues, followed by 1 day in room temperature. |

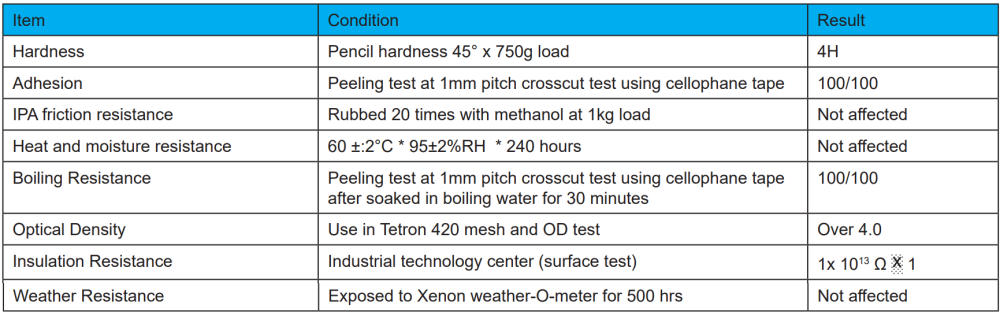

HF GV2 RX01 series is two part reaction ink developed for tempered glass. This series is an environmentally-friendly product, the percentage of Chlorine and Bromine is 900ppm and total Halogen is below 1,500ppm. In addition, HF GV3 RX01 series conduct scarcely. It is a three part ink developed for tempered glass.

| Ink type | Three part reaction acrylic ink |

| Features | Gloss finish and excellent in leveling HF GV3 RX01 Series can adhere to glass at low temperature and keep up with the physicality test of every kind. HF GV2 RX01 Series can adhere to glass at low temperature and keep up with the physicality test of every kind. |

| Diluent | T-980 |

| Washup | T-31 |

| Screen Mesh | T-250-420/inch fabric are recommended |

| Mixing ratio | HF GV3 RX01 710, Other colors: A Hardener: CARE 183 = 100:15:2 HF GV3 RX01 120: A Hardener: CARE 183 = 100: 10:2 HF GV2 RX01 710, Other colors: CARE 182 = 100:2 HF GV2 RX01 120: A Hardener: CARE 182 = 100:2 |

| Drying | 120°C x 30min is recommended |

| Notes | • Drying more than 40min at 120°C may help to improve the alcohol resistance. • Please follow the ratio of additive and adjust viscosity with diluents. Once ink is mixed HF GV3 RX01 and additives, the ink will get thicker about three hours at room temperature, so please dilute. • Addition (1%) of CARE 111 to the ink may help to improve the foaming printing problems. • When HF GV3 RX01 Series lose its performance because of the influence of environment and time, please add 1% of CARE 183. • Pot life is approximately 7 hours, so please do not use after 7 hours. • Please check the performance under long storage. |

| Ink | HF GV3 RX01 710 Black |

| Material | Tempered Glass |

| Screen Mesh | T-420/ inch |

| Squeegee | Urethane medium-hard |

| Printing | Hand Printing |

| Mixing Ratio | HF GV3 RX01 710: A Hardener: CARE183=100:15:2 |

| Diluents | T-980 10% |

| Drying Condition | 120°C x 30min |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)