Call us at

(+91) 8800090671

Email us at

Call us at

Email us at

The SG410 series is a family of urethane resin-based, soft and thermoplastic inks for printing on synthetic leather, leather, synthetic fabric, etc.

| Ink type | Air-drying ink that forms a soft film as the solvent evaporates. |

| Usage | Flexible finish on synthetic leather, synthetic fabric, etc. |

| Drying time | Dries naturally (set to touch) in 30 minutes at room temperature (20°C) or quicker by thermal curing. |

| Adhesion | Outstanding adhesion on synthetic leather, synthetic fabric, etc., but not on surfaces with waterrepellent coating. Add SG410 hardener (10%) to increase adhesion. Test prior to printing. |

| Diluent | Standard solvent (T-941), slow-dry solvent (T-942), retarder (T-980). |

| Wash-up | Use T-905 |

| Note | The ink’s viscosity is largely determined by the amount of solvents. The inks in this series are relatively more viscous than others. Use T-941 as needed to adjust viscosity. Mesh-clogging might occurs when printing in 800 medium, silver, fluorescent color. Use retarder solvent or SG410-Y0802 replace of 800 medium. We also offer Organic Tin-Free SG410YS series. |

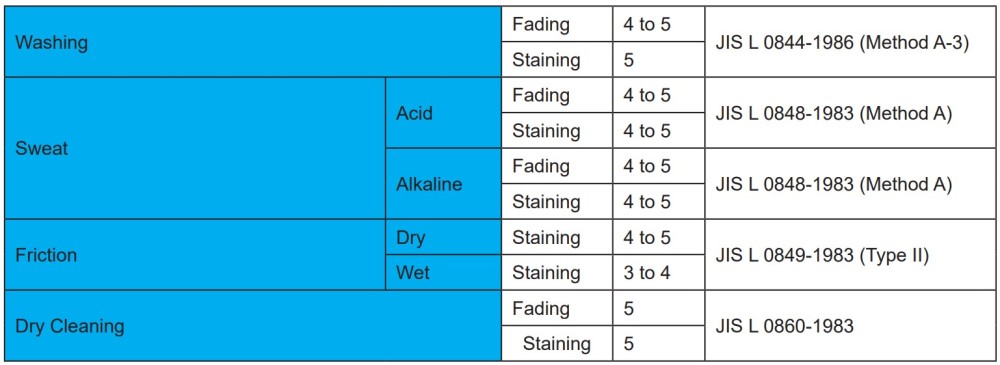

| Material | Printed on nylon cloth using SG 410 hardener (10%), dried at 120°C for 30 minutes. |

| Testing Institute | Japan Synthetic Textile Inspection Institute Foundation (Hokuriku branch). |

As a partner who thinks about the future and colors the moment, we will realize our value contribution to society.

09 to 17.30 (Except Sunday & holiday)